Shingle Belting's truly endless TrenSep separator belts are designed with many years of application experience and manufactured on state-of-the art equipment. This equipment was designed to eliminate the construction inconsistencies of belts made on autoclaves by applying consistent heat and pressure throughout the bonding process.

Shingle Belting's TrenSep truly endless belts are designed for maximum performance on separating and desinewing equipment in the Meat, Poultry, Seafood, and other industries. Consisting of the highest quality raw materials, the rubber and thermoplastic covers and tensile fabrics have been developed to solve problems for OEMs and End Users worldwide.

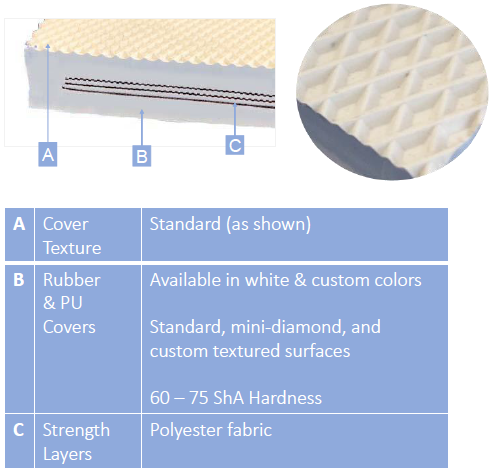

The rubber and thermoplastic covers are available in a variety durometers and can be provided with different surface impressions to maximize belt life and throughput performance.

The premium rubber covers, thermoplastic covers, and reinforcement materials result in truly endless belts that offer maximum performance.

Characteristics

- Specially compounded TrenSep rubber and thermoplastic covers are designed for maximum abrasion resistance and uniform pull throughout the belt's life.

- High tensile fabric for low elongation.

- Excellent internal adhesion eliminates delamination and "chunking".

- Manufactured truly endless, TrenSep belts have no splice that can fail.

- High coefficient of friction covers are engineered with the proper elasticity to resist compression and maximize cover wear.

Industries Served

- Meat and Poultry

- Seafood

- Agricultural

- Fruit and Vegetable Processing (apples, pineapples, potatoes)

- Product Re-wrap

- Miscellaneous Industries

Documents

To view these documents, you need Adobe Acrobat Reader. You can download a free copy from the Adobe web site.

To view these documents, you need Adobe Acrobat Reader. You can download a free copy from the Adobe web site.